Introduction

According to ISO surveys, nearly 30% of manufacturing projects are delayed due to design-stage oversights in manufacturability. In one real case, a medical device component with overly thin wall thickness was scrapped in bulk, resulting in losses of over one million dollars. For engineers, procurement managers, and manufacturing business owners, understanding and avoiding these mistakes not only reduces costs but also ensures reliable delivery. This article will analyze key pitfalls in CNC Machining Services, supported by industry standards and real-world cases.

H2: Why Do Design Errors Lead to Huge Losses?

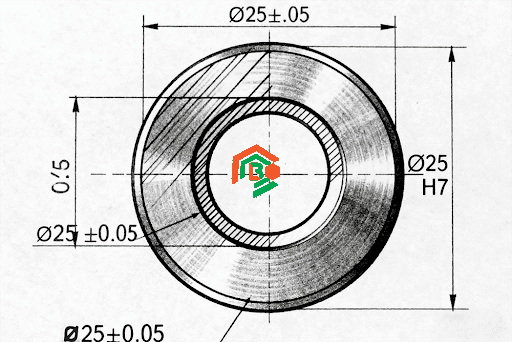

H3: Mistake 1 – Ignoring Tolerance Control

l Problem: Drawings fail to specify tolerances, resulting in parts that cannot be assembled.

l Cause: Lack of understanding of ASME Y14.5 standards.

l Solution: Apply standardized tolerance systems to ensure consistency.

l Benefit: Reduce scrap rates and rework costs.

Authority reference: ASME Y14.5 Dimensioning & Tolerancing emphasizes the importance of geometric tolerances. Interpretation: By unifying symbols and rules, this standard helps engineers avoid assembly errors during the design stage, thereby improving overall manufacturing efficiency.

H2: How to Choose the Right Machining Process?

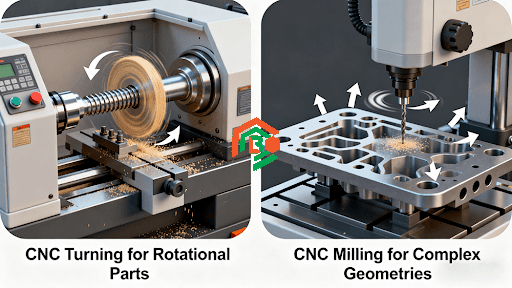

H3: Mistake 2 – Confusing Turning and Milling Applications

l Problem: Designs fail to consider process differences, doubling machining costs.

l Cause: Insufficient knowledge of process characteristics.

l Solution: Match part geometry with the most suitable process.

l Benefit: Optimize production efficiency and reduce machining time.

Natural phrasing: To optimize costs, understanding the difference between CNC turning and milling is critical. An industry guide provides detailed insights (Precision Turning vs. CNC Milling: Choosing the Best Process for Your Part). This guide, based on ASME Y14.5 standards, highlights the importance of tolerance control – ignoring it may increase scrap rates by 20%.

Figure 2. CNC machining relies on two main processes: Turning, where the workpiece rotates to create rotational parts, and Milling, where a rotating tool cuts stationary material for complex geometries.

H2: Why Do Supplier Certifications Determine Project Success?

H3: Mistake 3 – Overlooking Quality Management Systems

l Problem: Choosing uncertified suppliers leads to inconsistent quality.

l Cause: Neglecting certification requirements.

l Solution: Prioritize suppliers with ISO 9001 and IATF 16949 certifications.

l Benefit: Reduce project risks and ensure consistent delivery.

Authority reference: IATF 16949:2016 highlights automotive industry quality management requirements. Interpretation: This standard requires suppliers to establish full-process traceability, ensuring every production step is controlled, which significantly reduces batch defect rates.

H2: Why Does Ignoring Material Selection Increase Costs?

H3: Mistake 4 – Neglecting Material Properties

l Problem: Using unsuitable materials increases machining difficulty.

l Cause: Lack of material machinability analysis.

l Solution: Match materials with processes during the design stage.

l Benefit: Reduce tool wear and improve machining efficiency.

Industry case: An aerospace part made of high-hardness titanium shortened tool life, increasing machining costs by 40%. Selecting alternative materials significantly reduced costs.

H2: How to Prevent Delivery Delays?

H3: Mistake 5 – Lack of Standardized Processes

l Problem: Project management relies on ad-hoc inspections, causing delays.

l Cause: Absence of systematic quality control.

l Solution: Establish standardized processes with traceability.

l Benefit: Shorten delivery cycles and improve customer satisfaction.

Author Bio

This article was authored by LS Manufacturing, a company certified with ISO 9001, IATF 16949, ISO 13485, and AS9100D. LS Manufacturing provides CNC Machining Services and helps global clients solve cost and quality challenges in precision part manufacturing. Download the “DFM Design Checklist for Precision Parts” to increase your project success rate.

FAQs

1. What is the difference between CNC Machining Services and traditional machining? → CNC machining ensures high precision and consistency through numerical control, while traditional machining relies on manual experience with higher error rates.

2. How can I evaluate supplier reliability? → Check for ISO 9001 or IATF 16949 certifications and request quality management documentation.

3. What is the main difference between CNC Turning and CNC Milling? → Turning is ideal for round parts, while Milling is suited for complex geometries.

4. How can CNC machining costs be reduced? → Optimize tolerances during design, select suitable materials, and avoid unnecessary complexity.

5. Why is ASME Y14.5 important in manufacturing? → It standardizes tolerance symbols and rules, ensuring clear communication between design and manufacturing, reducing assembly errors.