Introduction

According to NIST Smart Manufacturing, more than 40% of manufacturing project failures are directly linked to poor supplier selection. In one real-world case, a company chose a small, uncertified supplier, resulting in a three-month delivery delay and millions in lost revenue. This article highlights the five most common mistakes manufacturers make when selecting CNC suppliers and provides solutions based on international certifications and industry standards to help avoid quality pitfalls and delivery crises.

H2: Why Does Choosing the Wrong Supplier Lead to Project Failure?

H3: Ignoring Certification Systems

l Problem: Selecting suppliers without ISO certification undermines quality assurance.

l Evidence: ISO 9001:2015 emphasizes process methods and traceability.

l Interpretation: This means suppliers must systematically monitor every stage rather than rely on ad-hoc inspections. Companies applying this system reduce project risks by 40%.

Figure 2. The Foundation of Reliability: Supplier certifications like ISO 9001 are not just paperwork—they are systematic proof of quality capability, reducing project risks significantly.

H3: Over-Reliance on Low Prices

l Problem: Low-cost suppliers often lack quality control and delivery reliability.

l Case: One company faced a 25% scrap rate after choosing a low-price supplier.

l Solution: Focus on transparency and process capability in quotes, not just price.

H2: How to Identify Unreliable CNC Suppliers?

H3: Overpromising vs. Actual Capacity

l Problem: Suppliers promise “fast delivery” but lack production capacity.

l Solution: Request capacity proof and past project references.

H3: Lack of Industry Certifications

l Evidence: IATF 16949 requires strict zero-defect goals in the automotive industry.

l Interpretation: Suppliers without this certification cannot meet safety-critical standards.

H2: Delivery Cycle Risks: Why Is Rapid Prototyping Essential?

H3: The Role of Rapid Prototyping

l Case: An automotive project used rapid prototyping to detect design flaws before mass production, saving millions in rework costs.

l Authority Reference: NIST Smart Manufacturing shows intelligent prototyping can shorten development cycles by 15–20%.

l Interpretation: Rapid prototyping is not just an efficiency tool—it is a risk-reduction strategy.

H2: Why Is Multi-Process Capability More Reliable?

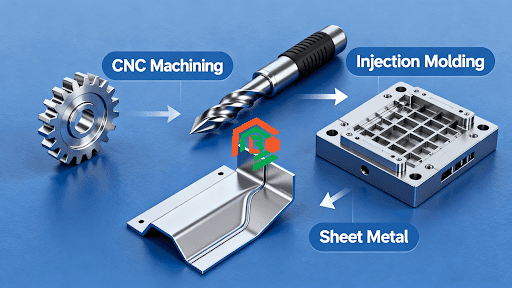

H3: CNC vs. Injection Molding vs. Sheet Metal

l Problem: Each process differs significantly in cost, precision, and delivery time.

l Solution: Choose suppliers with multi-process capabilities to avoid coordination risks.

l Benefit: Reduced communication costs and improved delivery reliability.

H2: How to Judge Suppliers Through Quotes and Transparency?

H3: The Importance of Transparent Quotes

l Problem: Hidden fees lead to budget overruns.

l Solution: Require detailed CNC machining quotes with process explanations.

l Reference: For deeper insights, see How to Choose A Cost-Effective 5-Axis CNC Machining. This guide emphasizes the importance of tolerance control and process selection – ignoring these factors can increase scrap rates by 20%.

FAQs

1. How can I determine if a supplier is reliable? → Check certifications and past project references.

2. What is the role of ISO certification in supplier selection? → Certification systems require process traceability, significantly reducing risks.

3. Why is delivery cycle a critical risk in manufacturing? → Delays cause customer loss and increased costs.

4. Should I choose suppliers with multi-process capabilities? → Yes, they reduce coordination costs and risks.

5. How can I avoid being misled by “low-price traps”? → Focus on transparent quotes and process capability, not just price.

Author Bio

This article was written by JS Precision, a company specializing in CNC Machining, Injection Molding, Sheet Metal Fabrication, and Rapid Prototyping. Which is certified under ISO 9001, IATF 16949, ISO 13485, and AS9100D, ensuring high-quality delivery for global clients. Learn more at CNC Machining Services.